|

|

|

|

The data forming the basis on this report has been collected through

the joint effort of Acona AS.

Acona

has gathered the data to the best of our knowledge, ability, and in good faith

from sources to be reliable and accurate.

Acona

has attemted to ensure the accuracy of the data, though, Acona makes no

representations or warraties as to the accuracy or completeness of the reported

information.

Acona

assumes no liability or responsibility for any errors or omissions in the

information or for any loss or damage resulting from the use of any information

contained within this report.

This

document may set requirements supplemental to applicable laws. However, nothing

herein is intended to replace, amend, supersede or otherwise depart from any

applicable law relating to the subject matter of this document.

In

the event of any conflict or contradiction between the provision of this

document and applicable law as to the implementation and governance of this

document, the provision of applicable law shall prevail.

Revision and Approval Form

|

Technical report |

|

Title |

|

ACES User Manual |

|

Revision History |

Date |

Prepared |

Approved |

|

|

1.0 |

01.10.2014 |

Acona |

Acona |

|

Name |

Date |

Signature |

|

Prepared by |

|

|

|

Acona |

01.10.2014 |

|

Table of Contents

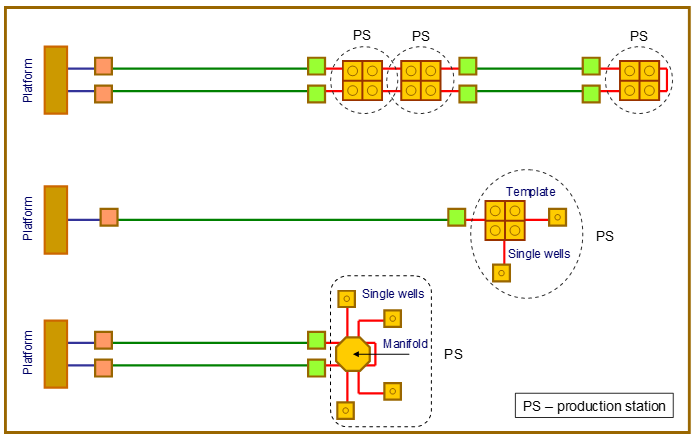

2.1 Types of field development

3.2 Well maintenance/intervention

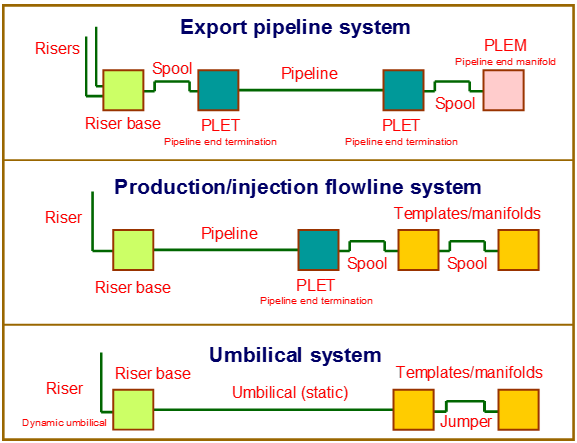

5 UFR Umbilical, flowline, riser

5.2 Diameter and thickness of pipelines

8 Tie-back projects with topside

modifications

8.2 Input definition for topside modification in tie-back

projects

9 Allowances and contingencies

12 Units and conversion factors

Figures

Figure 1 - Illustration of

overall structure

Figure 3 - Rig categories

and classes of intervention

Figure 4 -Subsea

production stations examples.

Figure 5 - Definition of

terminology

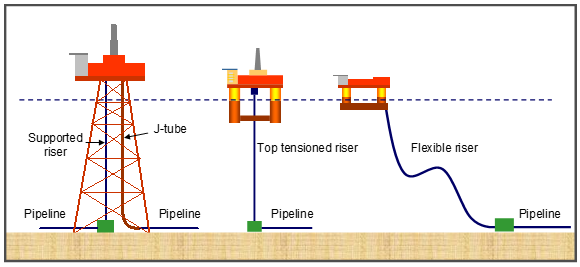

Figure 6 - Riser concepts

- illustrations

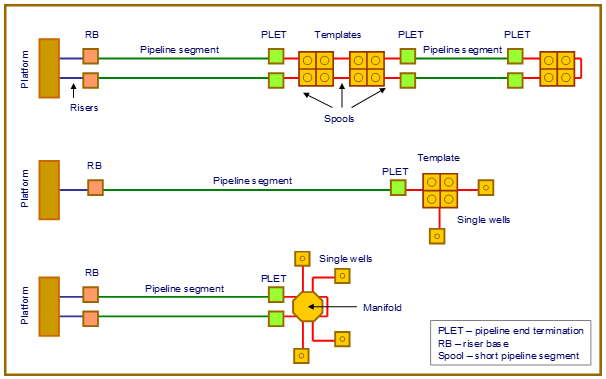

Figure 7 -

Flowline/pipeline groups - examples

Figure 8 - Illustration of

direct electric heating

Figure 9 - Illustration of

pipe-in-pipe

Figure 10 - Illustration

of platform concepts

Figure 11 - Functionality

of platform concepts

Figure 12 - Platform main

functional areas

Figure 13 - Inlet system A

and B

Figure 14 - Illustration

of the full processing case with two inlet systems

Figure 15 - Illustration

of tie-back projects

Figure 16 - Illustration

of space/area challenges in modification projects

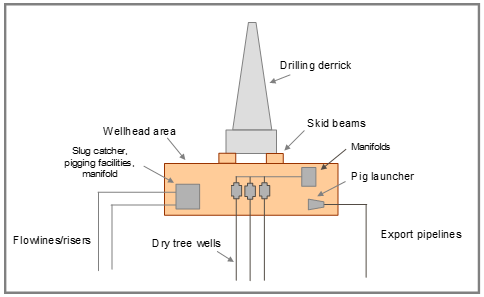

Figure 17 - Tie-in of

wells, flowlines/risers and export pipelines to platform topsides

Figure 18 - Illustration

of modification weight definition

Figure 19 - Pre-fabricated

manifold assembly for a tie-back project

Figure 20 - Allowances and

contingencies

|

DEH |

Direct electric heating |

ESP |

Electric submersible pump |

|

EUR |

Euro |

FPSO |

Floating production, storage and offloading unit |

|

MODU |

Mobile offshore drilling unit |

MSL |

Mean sea level |

|

NOK |

Norwegian kroner |

NPV |

Net present value |

|

PLEM |

Pipeline end manifold |

PLET |

Pipeline end terminal |

|

Sm3 |

Standard cubic meter |

Sm3 oe |

Standard cubic meter oil equivalent |

|

TLP |

Tension leg platform |

TVD |

Total vertical depth |

|

USD |

U.S. dollar |

|

|

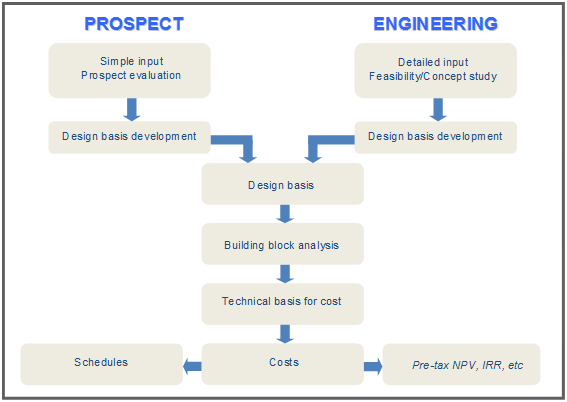

There

are two options for how to use the program; the PROSPECT version and the

ENGINEERING version

The

data basis and the calculation methods are the same for the two versions. But

the input to the analyses is quite different.

Option 1 Prospect analyses

For prospect analyses the

available design basis information is very preliminary, limited and immature.

Only a few input parameters are

required. Additional design basis assumptions are generated automatically based

on assumptions.

Option 2 Engineering;

feasibility and concept studies

For feasibility and concept

studies the design basis is more mature, and technical parameters may be

available from other studies. A more detailed

list of input parameters will be required.

The descriptions in the

following sections relate to the Engineering version

Figure 1 - Illustration of overall

structure

The following general input is

required:

·

Name of project

·

Cost reference year. All costs

(USD, NOK or USD) are real costs

related to this year.

·

Water depth for the field

(normally the at platform location)

·

Location of field (four

different alternatives)

·

Type of project, see below. A stand-alone project always includes a

new platform. A tie-back project

includes some platform modifications

·

Initial reservoir pressure

(bar)

For specific cash flow analyses

it is necessary also to specify:

·

Number of stream days per year

·

Discount rate for NPV

calculations

·

Recoverable volumes for

oil/condensate and gas given in specified units

·

Price and tariff or

oil/condensate and gas given in specified units

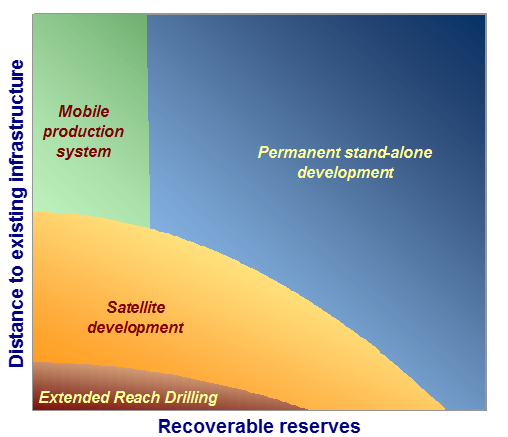

In the illustration below it is

distinguished between four types of field development.

Mobile production systems and

permanent stand-alone developments are both stand-alone

projects. Mobile systems are suitable for small fields with short field

life.

Satellite developments are tie-back projects suitable for small to

medium size fields not too far away from existing infrastructure.

Extended reach drilling can be

used in special cases where new hydrocarbons are found within drilling reach

from existing infrastructure with drilling facilities.

Up to 10 well groups can be defined. All wells in one group are identical. For

a specific case with several wells it is possible to define only one well

group. The well group will then represent an average well or typical well.

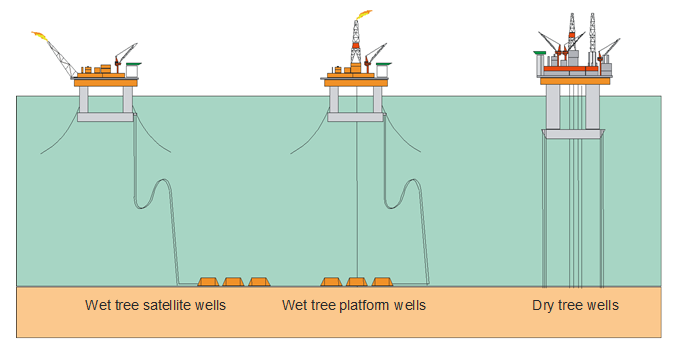

Figure 2 - Types of wells

The well function must be defined. There are three alternatives:

Producer, water injector and gas injector.

The well type must be defined. There are three alternatives: Dry tree

well, wet tree platform well and wet tree satellite well. A dry tree well and a

wet tree platform well is located underneath the platform, while a wet tree

satellite well is located some distance from the platform.

The drilling method must be defined. There are three alternatives:

Platform rig, jack-up MODU and semisubmersible MODU.

The true vertical depth (TVD) must be defined. This is the vertical

distance from mean sea level (MSL) to the bottom of the well.

The horizontal reach must be defined. This is the horizontal distance

between the wellhead the bottom of the well.

The horizontal section must be defined. This is the length of the

horizontal section the well.

The wells can have artificial lift. Gas lift or ESPs can be

selected.

The average progress rate for drilling (m/day) must

be defined.

The completion time must be defined. This is the number of days needed

for completion of the well.

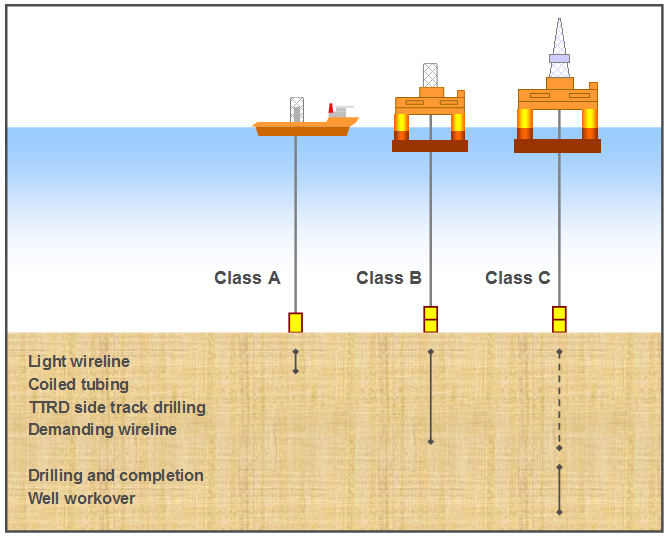

It is distinguished between

three classes of intervention: A light, B

medium, C heavy. For each class of intervention it is necessary to define frequency and duration.

The frequency is the number of interventions per well per year.

The duration is the number of days needed for each intervention.

Figure 3 - Rig categories and classes of intervention

Up to 10 different production

stations can be defined. Each production station comprises one or more wells.

·

The number of X-mas trees must be defined.

·

The number of template well slots must be defined. The number of slots

may be higher than the number of X-mas trees.

·

The number of single well slots must be defined. A single well may be

connected to a template/manifold or directly to the production platform.

·

It has to be specified whether

template wells and single wells will have a protection structure or not.

·

The pressure class for the X-mas trees must be defined. There are three

alternatives: 5000 psi, 10000 psi and 15000 psi.

·

The number of multiphase flow meters associated with

each production station must be defined.

·

The number of multiphase pumps associated with each

production station must be defined.

·

The distance between the production station and the platform must be

defined.

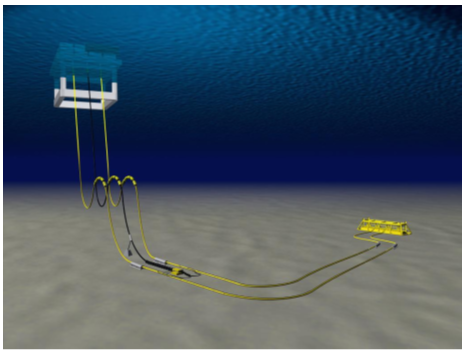

Figure 4 -Subsea production stations examples

Up to 10 different groups of

flowlines and risers can be defined. Each group can comprise several pipeline

segments, spools and risers.

Figure 5 - Definition of terminology

The function of each group must be defined. There are five options: Oil

export, gas export, water injection, gas injection, wellstream production. A gas lift line can be considered as a gas

injection line.

The type of material must be defined. There are four

options: Carbon steel, clad steel, Cr steel, flexible pipe.

The surface protection must be

defined. There are five options: No protection or cover, coating, insulation,

insulation with direct electric heating (DEH) and pipe-in-pipe.

The installation/lay method must be defined. There are three options:

S-lay, J-lay and reeling.

The amount of gravel dumping must be defined. There

are four options: no gravel dumping, little, medium and high degree of gravel

dumping.

The type of risers must be defined. There are four

options: J-tube, supported steel riser, tensioned steel riser, flexible riser.

Figure 6 - Riser concepts - illustrations

J-tubes and supported risers

are only used with fixed platforms. J-tubes are used for smaller diameters of

flowlines (<16) while supported risers can be used for large diameters.

Top-tensioned risers are used

with tension leg platforms, spars and jack-ups.

Flexible risers can be used

with all types of platforms.

The total length of pipeline per group must be defined. There may be

several pipe segments in the group, but they all have the same characteristics.

The number of pipe segments per group must be defined.

The number of spools per group must be defined. A

spool is a relatively short pre-fabricated pipe element that accommodates

thermal expansions and is used for connecting different parts of the system.

The number of pipeline end terminations (PLETs) per

group must be defined.

The number of pipeline end manifolds (PLEMs) per group

must be defined.

The number of risers per group must be defined.

(The number of riser bases is

determined automatically).

It has to be specified whether

HIPPS (high integrity pressure protection system) is used, or not.

Figure 7 - Flowline/pipeline groups - examples

Diameter

and thickness for each pipeline group can be

given as input.

Diameter and thickness is also

be proposed by the program. In that case the following input must be given:

·

Flow capacity

·

Inlet pressure

·

Pressure drop in pipeline

The flow capacity (Sm3

oe/day) can for this purpose be given

as:

F

= Oil + 1000 Gas + W

Where Oil is the oil flow in Sm3/d, Gas is the gas flow in mill.Sm3/d and Water is the water flow in m3/d.

If the proposed values are to

be used, the selected values must be put equal to the proposed values.

Length

and number of segments for umbilicals and

electric power cables must be defined.

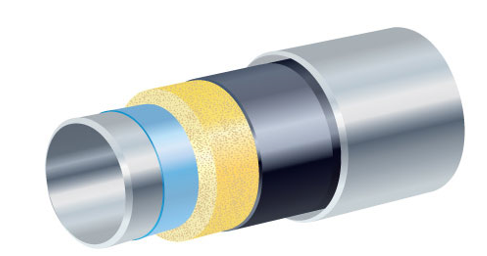

Figure 8 - Illustration of direct electric heating

Figure 9 - Illustration of pipe-in-pipe

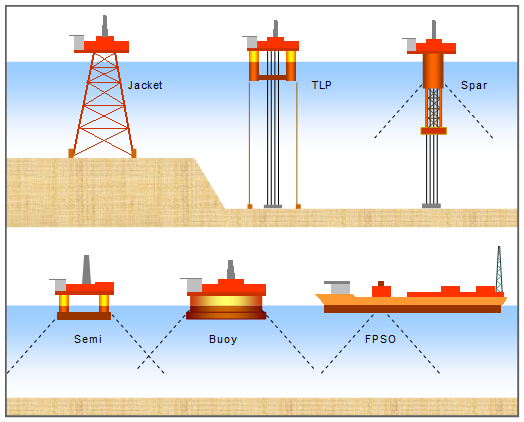

The type of platform substructure must be defined. There are five

alternatives:

·

Fixed steel platform (jacket)

·

Tension leg platform (TLP)

·

Spar platform

·

Semisubmersible platform (Semi)

·

Buoy

·

Production ship (FPSO, floating

production, storage and offloading unit)

Figure 10 - Illustration of platform concepts

The dimensions and weight of

the substructure will be determined on the basis of topside weight and oil storage

volume. A typical oil storage volume is 150000m3. (For Spar

platforms only smaller volumes should be considered).

·

Integrated

oil storage can only be specified for Spars, Buoys and FPSOs! Fixed platform,

TLP and semi will have to use a leased storage tanker.

·

Dry

tree wells can only be specified for Jackets and TLPs!

·

Drilling

rig can not be used on FPSOs!

·

A Jacket is attached to the sea

bottom by piles.

·

A TLP is attached to the sea

bottom by tension legs (tethers) and piles.

·

Spars, Semis, Buoys and FPSOs

are anchored by means of a chain-wire-chain system and suction anchors.

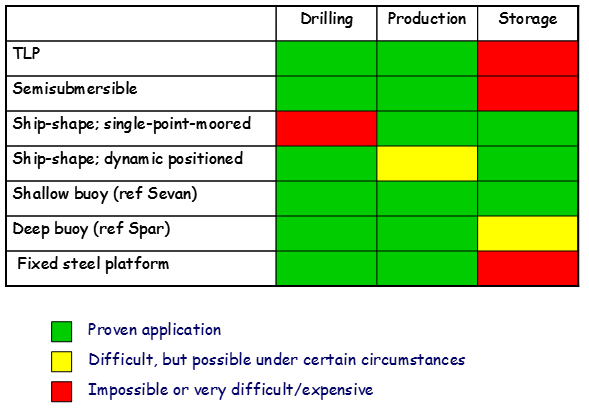

Figure 11 - Functionality of platform concepts

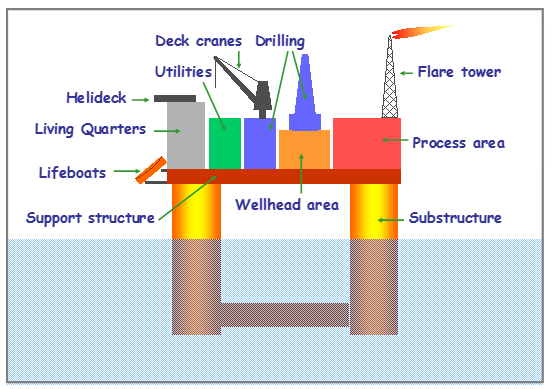

The main elements of a platform

are shown in the illustration below. There are five main functional areas:

·

Living quarters with helideck

·

Utility area, including power

generation and water injection facilities

·

Drilling area, including

derrick and mud systems

·

Wellhead area

·

Process area

Other significant pieces of

equipment are flare tower, deck cranes and life boat stations. In some cases

there are special support structures for modules and heavy equipment packages.

Figure 12 - Platform main functional areas

The number of beds must be defined.

This is the basis for weight estimation.

It has to be specified whether

a drilling package is to be included

or not.

The maximum well length must be defined. The weight of the drilling

package is scaled on the basis of maximum well length.

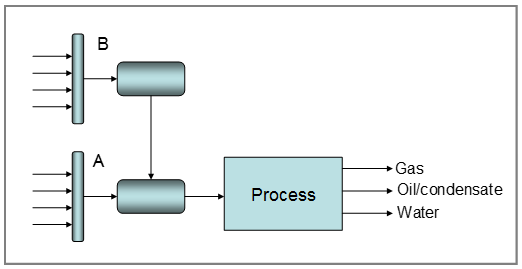

The platform can have one or

two inlet systems, see illustration below. System B has higher pressure than

system A (or equal).

Figure 13 - Inlet system A and B

For each of the two systems the

following input parameters have to be defined:

·

The oil production rate (capacity) must be defined.

·

The gas production rate (capacity) must be defined.

·

The inlet separator pressure must be defined.

·

The up-stream shut-in pressure must be defined.

·

The number of dry tree well slots must be defined.

·

The number of riser slots must be defined (riser slots related to

oil/gas export are not to be included in this number).

(Guidance: suggested values for

the up-stream pressure are shown)

If there is only one inlet

system, no data are to be given for system B.

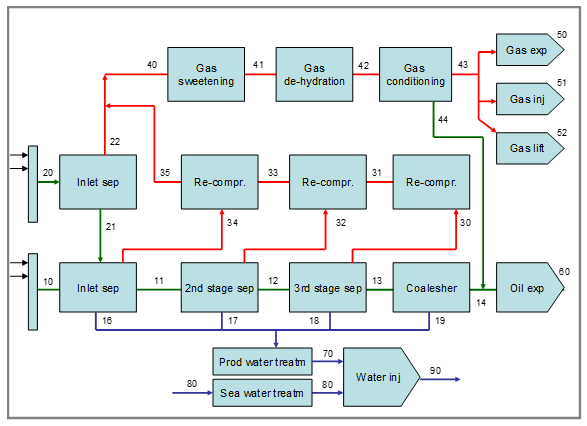

The process concept case must be defined. There are five alternatives:

·

Concept 1: full processing of

oil/gas/water, see illustration below

·

Concept 2: simplified process;

one-stage separation only

·

Concept 3: simplified process;

one-stage separation with water removal; oil and gas export in common pipeline

·

Concept 4: no processing;

wellstream export

·

Concept 5: Tie-back project.

The host platform is assumed to be a full processing platform with one inlet

system. If the tie-back project needs a separate in-let system, two in-let

systems must be specified. Existing systems are up-graded/modified.

Figure 14 - Illustration of the full processing case with two inlet systems

The following parameters have

to be defined:

·

Maximum liquid capacity; the

maximum combination of oil/condensate and water. Guidance: (oil3/2 +

water3/2)2/3 where oil

is the maximum oil production and water

is the maximum water production

·

Produced water treatment

capacity. Guidance: about 75 percent of the oil production capacity

·

Water injection capacity.

Guidance: about 150 percent of the oil production capacity

·

Gas export capacity.

·

Gas injection capacity

·

Gas lift capacity

·

Oil/condensate density (API

gravity)

·

Oil/condensate stabilization

(stable oil/condensate for tanker transport)

Design

pressure (Guidance: suggested values are

shown)

·

Oil/condensate export pressure

·

Gas export pressure

·

Gas injection pressure

·

Gas lift pressure

·

Water injection pressure

Export

riser slots

·

Number of oil export riser

slots

·

Number of gas export riser

slots

Power

generation

·

Alternative 1: main power

generation and emergency power generation on platform

·

Alternative 2: main power

import via cable; emergency power generation on platform

Note: Gas export compressors

are always assumed to be powered by gas turbines!

Systems

that may or may not be included

·

Test separator

·

MEG regeneration system

(relevant for long tie-backs)

·

De-sulphatation of injection

water

·

Gas sweetening (removal of CO2

and/or H2S)

·

Gas conditioning (NGL

extraction)

·

Gas de-hydration (water

dew-point control)

·

Fiscal metering of

oil/condensate

·

Fiscal metering of gas

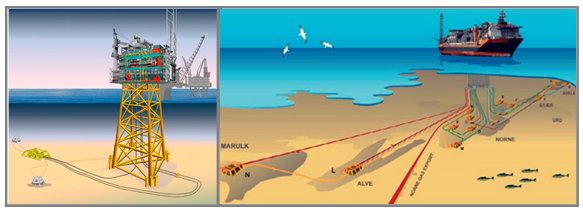

A tie-back concept is field

development concept with certain characteristics:

·

There are no manned facilities

on the field only a subsea well system or an unmanned wellhead platform

·

The well-stream is transferred

to an existing platform host platform

·

The host platform may supply

water and/or gas for injection

·

The host platform may be a fixed

platform or a floating platform

Figure 15 - Illustration of tie-back projects

There are several requirements

to a host platform:

·

The host platform must have

sufficient remaining service life

·

The host platforms must have

possibilities for tie-in of flowlines and umbilicals via existing or new

risers or J-tubes

·

Well control systems

must be installed on the host platform

·

An acceptable tie-in solution

may require a new inlet separator and metering system integrated with

the existing systems

·

The host platform must have sufficient

capacity in all main platform systems (process/utilities)

·

De-bottlenecking

can to some degree enhance the throughput

·

Installation of parallel

trains is normally not an option due to costs, and lack of space and weight

carrying capacity

·

Production and injection

profiles for the tie-back project are normally defined to match the

available capacities on the host platform. Timing of the tie-back project

is therefore essential

Installation of new equipment

may be limited by lack of space and weight carrying capacity. Verification of

the feasibility of potential modifications can be very complex, even for small

modifications

Cost estimates have a wider

range of uncertainty than estimates for new platforms. Use of 3D CAD models may

be required even for feasibility studies.

Figure 16 - Illustration of space/area challenges in modification projects

New equipment associated with a

tie-back project may include:

·

risers, pull-in and pigging

equipment, see illustration below

·

inlet separator

·

re-compression equipment (only

if the new in-let separator has a higher operating pressure than the existing inlet

separator)

·

metering system related to the

new inlet system

Figure 17 - Tie-in of wells, flowlines/risers and export pipelines to platform

topsides

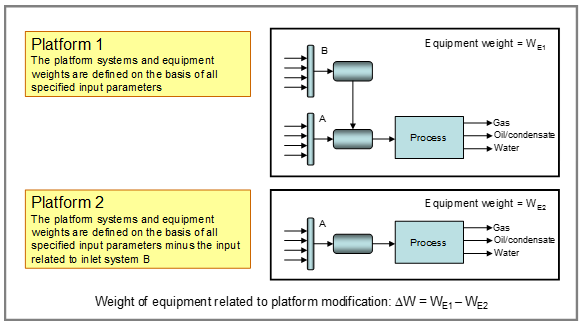

The topside modification

weights are based on differentials between two platforms; platform 1 and

platform 2.

Platform 1 is the modified host

platform, and platform 2 is the host platform before the modification, see

illustration below.

Figure 18 - Illustration of modification weight definition

This means that the platform

input must be given in such a way that the capacities reflect the design of the

modified host platform.

The process concept must be set

equal to: Process modification (

)

Inlet system B is dedicated to

the tie-back project. The input

related to system B must define the oil and gas volumes, the pressures, and the

number of slots needed.

There

are two options for inlet system B:

1)

Minimum modification: Direct tie-in to existing

inlet separator (select 1 inlet separator)

2)

Medium modification: Install a new inlet separator

and metering system with necessary adjustments to other systems (select 2 inlet

separators)

There can be cases where larger

modifications are required. This can be related to the age and functionality of

the host platform. In such cases it is recommended to carry out a specific

technical study including 3D CAD modelling of relevant areas of the platform.

Weights can then are given as direct input for cost estimation.

Base case should be to select

modification weights equal to the proposed weights.

New equipment and structures

may in principle be pre-fabrication onshore and installed offshore, or built

piece by piece offshore. The degree of pre-fabrication (rough estimate) must be

defined.

Figure 19 - Pre-fabricated manifold assembly for a tie-back project

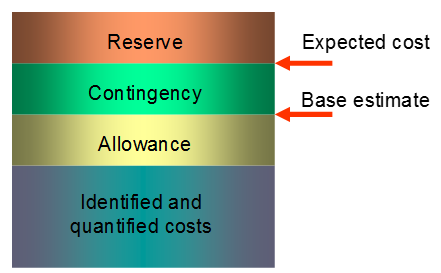

The following definitions are

used:

Base

estimate is the sum of the identified

quantities and costs and an allowance.

The

allowance is a quantity to be included

in the weight estimates (basis for cost) to account for inaccuracies and

incompleteness in the definition of equipment, components and materials.

The

expected cost is the sum of the base

estimate and a contingency. The expected cost is the basis for economic

evaluations.

Contingency

is a correction to compensate for the effects of skewed (non-symmetric)

distributions for each of the components in the estimate and to cover for

unspecified cost elements.

Contingency

shall cover for uncertainty within the given scope, which may lead to different

design* (design changes, design development, different execution method or

different timing).

Reserve:

If significant uncertainties in the project scope and frame conditions remain

at project sanction, the management or joint venture may decide to include a

project reserve.

*The

reason for a design change is most often that the original solution was

found unacceptable and substituted by a different and more expensive

solution. Therefore design changes cause cost increases rather than decreases!

Figure 20 - Allowances and contingencies

Removal costs are calculated on

the basis of estimated quantities for the field development system that is

defined in the program. No special input is required.

The physical elements to be

removed or secured are included in the following groups:

·

Wells (plugging and

abandonment)

·

Platform topsides

·

Platform substructure

·

Mooring lines, anchors, piles

·

Risers, conductors

·

Flowlines, umbilicals and

cables

·

Export pipelines

·

Subsea equipment and structures

·

Sea bottom clean-up

For each group the following

cost categories are considered:

·

Management of the removal

project

·

Engineering

·

De-commissioning

·

Removal operation including

transportation to shore

·

Dismantling and re-circulation

or disposal of materials

·

Contingency

Calculation of NPV and other

economic indicators are performed based on the general input and data

generated in the program.

For the Cost Engineering Module, Production profiles must be defined. Data

is entered year by year. The annual production can be estimated by:

Daily

Production x Production days per year

The number of production days/

year is defined by Stream days or Calendar days.

Oil production is set in Mill.Scm3.

Gas production is set in Bill.Scm3.

For the Prospect Evaluation Module, there are two options for production

profiles input: Alternative 1 and Alternative 2.

By choosing Alternative 1, the

program estimates a general production profile based on the input information

provided. Basis for calculation are the Recoverable volumes of Oil and Gas

specified, and the average stream days per year. The program will suggest two

values based on internal calculations:

·

Percentage of annual production

at plateau relative to total production

·

Percentage of accumulated

production at end of plateau.

These two parameters will

define the generic production profile. Please note that these values can always

be overwritten.

By selecting Alternative 2, the

process is similar to the Cost Engineering Module, where the annual production

for Oil and Gas must be defined as input.

There are two other parameters

to define in the Economy tab.

·

Include / exclude Removal costs

in NPV analysis

·

Lease / purchase of floating

production units

Currency:

NOK per USD = 6,00

NOK per EUR = 8,00

Volume:

1 barrel oil ≈ 159 litre

1 scm oil ≈ 6.29 barrels

1 tonne oil ≈ 1.18 scm oil

1 scm oil ≈ 0.85 tonne oil

1 scm gas = 35.315 scf gas

1000 scm gas = 1

scm o.e.

1 scm NGL = 1 scm

o.e

1 scm condensate

= 1 scm o.e.

Length:

1 ft = 0.3048 m

1 m = 3.2809 ft

1 in = 2.54 cm

1 km = 0.62137 miles

Numerical:

1 mill (M) = 1 million = 1x106

1 bill (G) = 1 billion = 1x109

Pressure:

1 bar = 14.5038

psi

1 psi = 0.0689

bar